As industries continue to evolve, the demand for advanced manufacturing techniques has never been more pronounced, leading to the emergence of innovative technologies like plasma spraying. By 2025, plasma spraying technology is set to revolutionize various sectors, including aerospace, automotive, and medical devices. This blog will delve into the cutting-edge trends in plasma spraying technology, exploring how businesses can leverage these advancements to enhance their operations.

Key to this transformation is the development and optimization of plasma spraying equipment, which plays a crucial role in improving coating performance and efficiency. We will discuss the latest innovations in plasma spraying equipment, their applications, and how understanding these trends can empower industries to stay ahead of the competition. Whether you're a manufacturer looking to upgrade your processes or an engineer interested in the latest techniques, this comprehensive guide will provide you with essential insights into the future of plasma spraying technology.

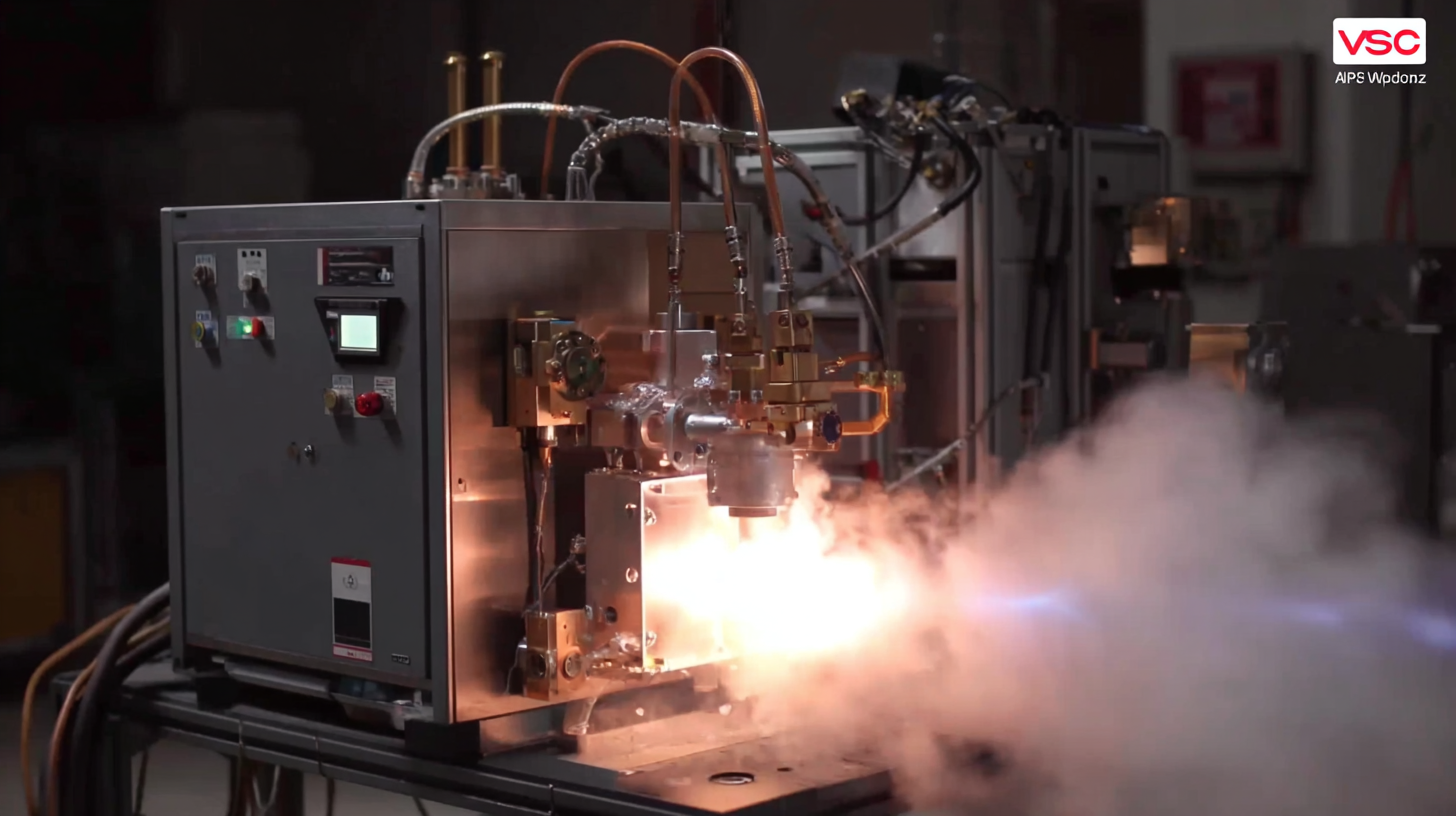

Innovative plasma spraying techniques are set to revolutionize manufacturing practices by 2025. As industries increasingly demand higher performance and durability from materials, plasma spraying offers a solution that combines versatility with precision. This technology utilizes high-energy plasma to melt coating materials, which are then sprayed onto a substrate. The result is coatings that exhibit superior adhesion, corrosion resistance, and wear performance, making them ideal for critical applications in aerospace, automotive, and medical sectors.

In 2025, we can expect to see advancements in plasma spraying processes, such as controlled atmosphere techniques and hybrid systems that integrate multiple spraying methodologies. These improvements will enhance the efficiency and quality of coatings while reducing material waste. Additionally, the incorporation of artificial intelligence and machine learning will enable real-time monitoring and optimization of the spraying process, ensuring consistency and reducing human errors. As manufacturers embrace these innovative techniques, they will not only improve product performance but also drive sustainable practices by decreasing resource consumption and scrap rates.

Plasma spraying technology is rapidly evolving, driven by various key industry applications that demand advanced solutions for surface coating and protection. The aerospace sector is at the forefront, requiring high-performance coatings to withstand extreme temperatures and corrosive environments. Similarly, the automotive industry is leveraging plasma spraying to enhance wear resistance and reduce friction in critical engine components, thereby improving efficiency and longevity.

Tip: When considering plasma spraying as a solution for your industry, it's crucial to assess the material compatibility and the specific environmental challenges that your components face. This evaluation will help in selecting the right coating materials and techniques.

In the medical field, plasma spraying technology is finding its way into the production of biocompatible coatings for implants and prosthetics. These coatings not only improve the integration of devices with human tissue but also enhance their wear characteristics, ultimately leading to better patient outcomes. As industries continue to innovate, the demand for sophisticated plasma spraying solutions is set to rise significantly.

Tip: Stay updated on the latest advancements in plasma spraying techniques, as emerging technologies can lead to breakthroughs in performance and efficiency that may benefit your applications. Leveraging these innovations can give your products a competitive edge in the market.

China is rapidly positioning itself as a leader in the plasma spraying technology sector, influencing global innovations and setting benchmarks for quality. With its commitment to advanced manufacturing and cutting-edge research, China is developing unique plasma spraying systems that enhance efficiency and effectiveness across various industries, including aerospace, automotive, and electronics. As companies leverage these innovations, they not only improve their product quality but also reduce production costs, establishing a competitive edge in the international market.

**Tip:** When considering plasma spraying technology, it is crucial for businesses to stay updated on the latest advancements in the field, particularly those emerging from China. Engaging with local manufacturers and participating in industry trade shows can provide valuable insights into the latest techniques and materials.

Moreover, as environmental concerns grow, Chinese companies are pioneering green plasma spraying solutions that minimize waste and energy consumption. This shift not only meets regulatory demands but also appeals to increasingly eco-conscious consumers. By adopting such sustainable practices, companies can enhance their reputations and tap into new markets.

**Tip:** Implementing sustainability at the core of plasma spraying operations can lead to significant cost savings and attract environmentally aware clients. Investing in research and development to explore eco-friendly materials and processes is essential for long-term success in this evolving industry.

| Trend Area | Description | Year of Impact | Impact Level |

|---|---|---|---|

| Advanced Materials | Research into new composites for enhanced durability and performance. | 2025 | High |

| Automation | Incorporation of AI and robotics for precision spraying and reduced waste. | 2024 | Medium |

| Eco-Friendly Practices | Development of sustainable materials and processes to minimize environmental impact. | 2023 | High |

| Industry Collaboration | Partnerships between academia and industry to foster innovation in plasma spraying. | 2025 | Medium |

| Data Analytics | Utilization of big data to optimize spraying parameters and enhance quality control. | 2024 | High |

Emerging trends in plasma spraying technology are increasingly pivoting towards sustainability and efficiency, reflecting a broader industry shift in 2025. Recent reviews in textiles have underlined the pressing need for sustainable production methods, highlighting the significant challenges and innovations necessary for the transformation of textile manufacturing. As companies strive for greener production, plasma spraying technologies could offer solutions that enhance efficiency while minimizing waste. It's posited that integrating plasma spraying with sustainable materials could lead to revolutionary advancements in both thermal management and environmental impact.

Moreover, the industrialization of eco-friendly practices has seen a pronounced rise in the use of alternative materials in various sectors, including construction and textiles. For instance, research into reused PET bottle panels indicates that they can significantly boost thermal insulation performance, aligning with sustainability goals. Similar integration in plasma spraying processes could not only extend the lifecycle of materials but also improve the overall performance of products. This fusion of technology and material science signifies a watershed moment in achieving sustainability benchmarks while addressing economic and ecological imperatives in manufacturing.

The implementation of plasma spraying technology in various industrial sectors presents a unique set of challenges and opportunities. One significant challenge lies in the integration of advanced plasma systems with existing manufacturing frameworks. Many industries still rely on traditional coating methods, and transitioning to plasma spraying demands not only substantial financial investment but also a shift in operational mindset. Training personnel to manage and maintain these sophisticated systems is critical, as improper handling can lead to inefficiencies and safety hazards.

On the other hand, the opportunities presented by plasma spraying technology are profound. This technique offers enhanced coating capabilities, improving wear resistance and thermal protection, which can lead to longer-lasting components and reduced maintenance costs. Industries such as aerospace, automotive, and medical technology stand to benefit significantly, as plasma spraying can create custom coatings tailored for specific applications. As more businesses recognize the advantages, the adoption of plasma spraying technology may accelerate, driving innovation and competitiveness in the marketplace. Embracing these changes will be essential for industries aiming to thrive in the rapidly evolving landscape of 2025 and beyond.

TradeManager

Teams

VKontakte