In the ever-evolving landscape of pet food production, quality stands as a cornerstone. Ensuring that each product is safe and nutritious is vital for pet health. However, the journey to high-quality pet food is not without its challenges. Variability in ingredient sources can lead to inconsistencies.

Pet food production begins with careful ingredient selection. Ingredients should be fresh and free from contamination. Yet, sourcing can vary greatly in quality. There’s a need for transparency from suppliers. Regular quality checks during manufacturing are essential. If processes are overlooked, the final product may fall short.

Moreover, staff training plays a critical role in maintaining quality. Knowledge about handling ingredients and machinery is crucial. Mistakes can easily happen without proper guidance. Thus, fostering a culture of quality awareness is crucial. Pet food producers must continually reflect on their practices to improve product integrity.

Quality standards in pet food production are crucial. They ensure that products are safe and nutritious for pets. According to a report from the Association of American Feed Control Officials (AAFCO), 95% of pet owners consider product quality when choosing food. This highlights the need for manufacturers to focus on stringent quality controls.

Ensuring quality involves multiple steps. Ingredient sourcing is vital. Ingredients should come from reputable suppliers. Regular audits and inspections help identify any potential hazards. The FDA emphasizes that contamination can occur at any stage of production. Therefore, maintaining hygiene and safety in manufacturing processes is essential.

Additionally, transparency in labeling is critical. Pet owners want to know what they are feeding their pets. Clear ingredient lists foster trust, but not all manufacturers comply. In a recent survey, about 25% of pet food products misrepresented their ingredients. This inconsistency can lead to pet health issues, which is a serious concern. Continuous improvement and adherence to regulations are necessary for building consumer confidence.

When formulating high-quality pet food, the choice of ingredients is crucial. Recent studies show that protein should form 30-50% of the total composition. Animal-based proteins, like chicken or fish, are ideal. They provide essential amino acids that support muscle health and overall wellbeing. However, many manufacturers overlook the quality of these protein sources.

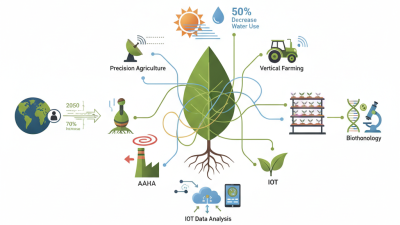

Incorporating whole grains, vegetables, and healthy fats enriches the nutritional profile. Ingredients like brown rice and sweet potatoes offer fiber and vitamins. Yet, it’s not just about adding variety. Ingredient sourcing requires transparency. According to industry reports, 70% of pet owners now demand clear labels. They want to know where their pets' food comes from.

A common pitfall is the reliance on fillers. Ingredients like corn and soy can be cheaper, but they provide less nutritional value. A recent survey indicated that 60% of pet food brands still use these fillers. This raises questions about production quality. Pet food must not only fill bowls but also meet nutritional standards. Manufacturers face challenges in balancing cost and quality, leading to potential shortcomings in their formulations.

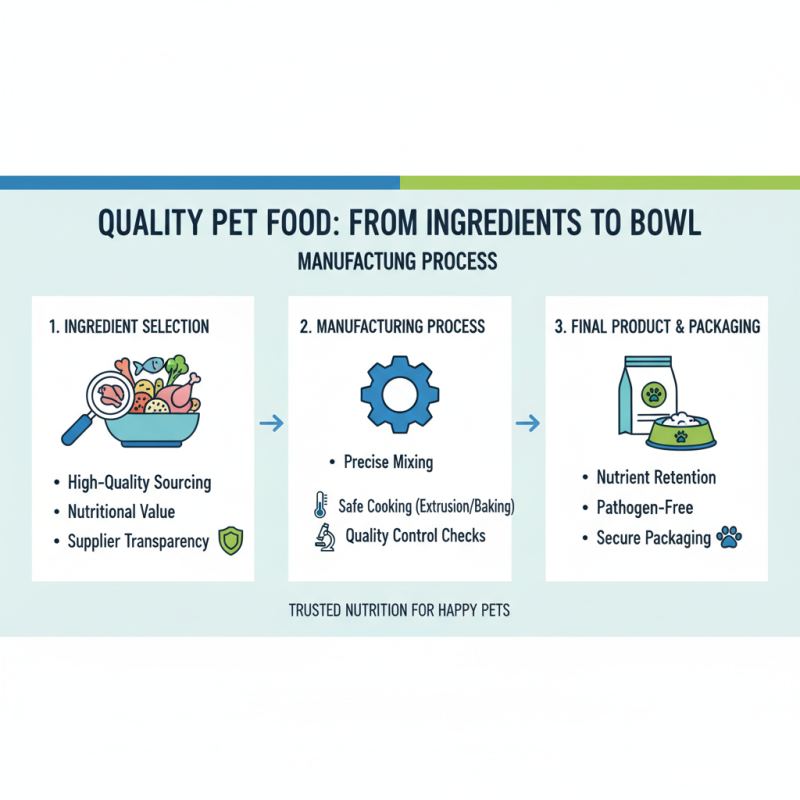

Manufacturing processes play a crucial role in ensuring quality in pet food production. The journey starts with ingredient selection. Choosing high-quality ingredients directly affects the final product. However, it can be challenging to source consistently safe and nutritious ingredients. Some suppliers might cut corners, impacting quality. Transparency in ingredient sourcing is vital.

Once ingredients are selected, processing methods must be scrutinized. Different methods, such as extrusion or canning, can affect nutrient preservation. Controlling temperatures and cooking times is essential. Yet, variations in equipment efficiency can lead to inconsistencies. Regular equipment maintenance and calibration can mitigate these risks. It's a minor step but can greatly impact the overall quality.

Quality assurance testing should be integrated throughout the manufacturing process. Testing for microbial contamination and nutrient levels is necessary. However, it's not foolproof. Some batches may still slip through the cracks. Thus, random sampling and ongoing monitoring become indispensable. Emphasizing a culture of quality within teams helps address these concerns and fosters continuous improvement.

Quality control is essential in pet food production. Each ingredient must meet stringent safety and quality standards. Regular testing ensures that every batch is free from contaminants. Staff should be trained to recognize potential issues. They can spot anything unusual during production. This proactive approach prevents larger problems down the line.

Monitoring equipment is another crucial aspect. Machinery needs routine checks to guarantee consistent performance. If a machine malfunctions, the entire production can suffer. Operators should report any irregular sounds or malfunctions immediately. Delays may occur, but it's better to prioritize safety. Sometimes, production speed can overshadow quality, leading to less-than-ideal outcomes.

Documentation plays a vital role in quality assurance. Keeping detailed logs allows for traceability and accountability. Any deviation from standards should be recorded and addressed. Reflection on past practices can lead to improvements. Regular reviews of procedures help identify weak points in the process. Empowering the team to voice concerns fosters a culture of quality.

Continuous improvement is vital in pet food quality management. Many manufacturers overlook small issues. These can lead to larger problems later. Research shows that 15% of pet food recalls are due to contamination. Regular audits and quality checks can help catch issues before they escalate. Companies often fail to maintain adequate documentation, which complicates compliance efforts.

Moreover, adopting a systematic approach is essential. Implementing Standard Operating Procedures (SOPs) can streamline production processes. A recent survey highlighted that 70% of firms with SOPs reported fewer quality issues. Training employees on these procedures is equally important. Staff should understand the significance of their role in maintaining quality. Without proper training, mistakes can easily happen.

Lastly, customer feedback plays a crucial role. Listening to consumer concerns helps improve product quality. Surveys reveal that 60% of pet owners prioritize ingredient transparency. Companies that respond to feedback tend to build stronger loyalty. Yet, many still struggle to act on this information effectively. Regularly reviewing feedback can spark necessary changes and enhance overall product quality.