The advancement of technology has significantly transformed various industries, and the food production sector is no exception. At the heart of this transformation are food production machines, which have emerged as essential tools that enhance efficiency, consistency, and quality in food manufacturing processes. These machines play a pivotal role in automating repetitive tasks, thus enabling manufacturers to scale operations while minimizing human error and operational costs. As demand for food continues to rise globally, the integration of these cutting-edge machines into the production workflow is not just beneficial but necessary for meeting the evolving needs of consumers.

Food production machines are designed to optimize every stage of food processing, from preparation to packaging. By incorporating innovative designs and technologies, these machines enable faster production rates, improved safety standards, and greater versatility in product offerings. From automated mixers to high-capacity ovens, the variety of equipment available allows producers to streamline operations, reduce waste, and ensure food safety compliance. As we delve deeper into the implications of food production machines on the industry, it becomes clear that they are not just tools of convenience but pivotal assets that are reshaping the landscape of food manufacturing for the better.

Food production machines encompass a wide array of devices and equipment designed to streamline the process of food manufacturing, preparation, and packaging. These machines include mixers, ovens, packaging systems, and conveyors, each contributing to enhanced efficiency and consistency in production. By automating tasks that were once labor-intensive, food production machines not only reduce the time and effort involved but also minimize the risk of human error, leading to improved quality in the final product.

Tips: When selecting food production machines, consider the specific needs of your operation. This includes analyzing the scale of production, the types of food being processed, and the desired output speed. Investing in versatile machines can facilitate adaptation to different production lines and changes in demand.

Moreover, these machines are designed with advanced technology, enabling users to monitor processes closely and adjust settings in real time. This not only enhances operational efficiency but also supports compliance with health and safety regulations in food production. Automation provided by these machines plays a crucial role in meeting the increasing demands of the food industry, allowing businesses to scale their operations effectively.

Tips: Regular maintenance and training for staff on how to operate these machines can lead to prolonged machine life and optimal production rates. Implementing a systematic maintenance schedule can prevent costly downtimes and ensure that machines operate at peak efficiency.

Food production machines have transformed the culinary landscape, ensuring efficiency, consistency, and high-quality outcomes in the manufacturing process. Understanding the key types of these machines can shed light on their critical roles in the food industry.

One of the most prevalent types of food production machines is mixers, which are essential for combining ingredients in various food types, from baked goods to sauces. These machines vary in size and capacity, catering to both small-scale and industrial operations. Another significant category includes food processors, known for their versatility in chopping, slicing, dicing, and pureeing ingredients, streamlining preparation tasks and reducing labor intensity. Additionally, ovens and fryers represent essential machinery that enhances cooking capabilities, allowing for uniform heat distribution and optimal cooking conditions.

Lastly, packaging machines play a crucial role in the food production process, ensuring that products are properly sealed and preserved for distribution. These machines help maintain freshness and safety, reflecting the industry's commitment to quality. Together, these key types of food production machines are integral to streamlining processes, improving productivity, and meeting the rising demands of consumers in the dynamic food market.

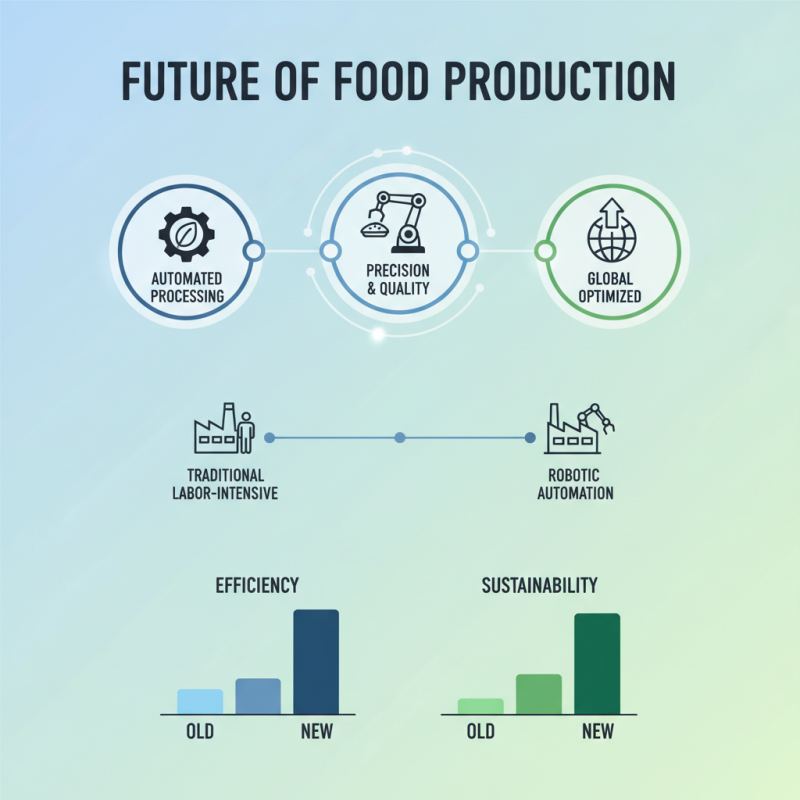

Innovations in food production technology have dramatically changed the landscape of the industry, enhancing efficiency and sustainability. One significant advancement is the integration of automation in processing plants, which has streamlined operations and reduced human error. Robots and automated systems are now employed for tasks ranging from sorting and packing to cooking and quality control. This not only speeds up production but also ensures consistent product quality, meeting the increasing demand for food worldwide.

Furthermore, the use of advanced data analytics and artificial intelligence has enabled producers to optimize their supply chains and inventory management. By analyzing consumption patterns and environmental factors, food manufacturers can make informed decisions that minimize waste and maximize output. These technologies also facilitate traceability, allowing producers to monitor the journey of food items from farm to table, ensuring safety and transparency for consumers. The ongoing evolution in food production technology is not just about increasing productivity; it is also paving the way for more sustainable practices that contribute to the overall health of the planet.

The automation of food production processes presents numerous advantages that are transforming the industry landscape. According to a report by the Food and Agriculture Organization (FAO), implementing automation can lead to a productivity increase of up to 30% in food manufacturing operations. This efficiency is largely due to the consistent quality and speed that machines can provide compared to manual labor, leading to reduced human error and minimized waste.

Moreover, the integration of food production machines significantly enhances food safety, as automated systems can maintain strict hygiene standards and traceability throughout the production chain. The International Society of Food Engineers has indicated that automation can reduce contamination risks by over 50%, ensuring that the final products meet stringent health standards.

Furthermore, these machines often utilize advanced technologies like IoT and AI, enabling real-time monitoring and adjustments that optimize resource usage, reduce energy consumption, and lower operational costs. With the food production machinery sector projected to grow at a CAGR of 6.5% through 2027, it’s clear that these innovations are not just trends; they are essential for meeting global food demand effectively and sustainably.

The landscape of food production machinery is undergoing a significant transformation driven by technological advancements and evolving industry needs. According to a report by MarketsandMarkets, the global food processing equipment market is projected to reach approximately $92 billion by 2026, growing at a CAGR of 6.5% from 2021 to 2026. This growth is largely attributed to the increasing demand for processed foods, the need for automation, and the rise of sustainable practices in food production.

Emerging trends such as the integration of artificial intelligence (AI) and the Internet of Things (IoT) are playing a pivotal role in optimizing food production machinery. Automation not only enhances efficiency but also minimizes human error, ensuring consistent product quality. A study by Grand View Research highlights that the automation of food processing equipment could reduce operational costs by up to 30% while improving production speed and accuracy. Furthermore, as consumers demand more transparency in food sourcing, manufacturers are implementing traceability technologies that depend on advanced machinery to monitor ingredients throughout the supply chain.

The future of food production machinery will also be characterized by the emergence of smart machinery capable of adapting to real-time data. Industry 4.0 principles are being embraced, allowing producers to implement predictive maintenance and quality control, which significantly reduces downtime. As reported by Mordor Intelligence, this shift towards smarter equipment is not just a trend but a necessary evolution that will define the competitive landscape of the food industry in the coming years.