In the competitive landscape of the food industry, efficiency is paramount. According to Dr. Alice Thompson, a renowned expert in food processing technology, "Innovative machines for food are revolutionizing the way we think about production.” This statement resonates deeply in an era where speed and quality are essential.

Machines for food processing not only improve output but also enhance food safety. For instance, automated systems reduce human contact, minimizing contamination risks. As these technologies advance, they introduce new challenges. Some manufacturers struggle to adapt, leading to gaps in their production lines. This means that while innovation is crucial, businesses must also focus on training and integration.

Moreover, the investment in machines for food often poses a financial risk for smaller companies. They may hesitate to upgrade outdated systems despite potential long-term benefits. It raises important questions: How do we balance innovation with practicality? As the industry evolves, continual assessment is vital for sustaining growth and efficiency.

Efficiency in food processing machines is essential for modern food production. These machines must be adaptable and reliable. Features that enhance efficiency include automation, durability, and ease of cleaning. Advanced technology helps streamline processes. Machines that reduce downtime lead to better productivity.

Embracing automation can significantly lower labor costs. However, one must balance machine reliance with skilled labor. Sometimes, machines malfunction or break down. This can interrupt production. Machine operators should be trained adequately to handle issues. Regular maintenance checks are crucial for avoiding sudden failures.

Tip: Invest in machines that have self-diagnostic features. This can help identify issues quickly. Choosing the right materials for construction is also important. Stainless steel often performs better versus cheaper options. Always assess the capacity required for your production needs. Overbuying can lead to wasted resources.

| Machine Type | Key Features | Efficiency Rating | Energy Consumption (kWh) | Innovation Score |

|---|---|---|---|---|

| Automatic Fillers | High-speed operation, adjustable volume | 95% | 15 | 8 |

| Vacuum Packaging Machines | Moisture sealing, oxygen removal | 92% | 12 | 9 |

| Conveyor Systems | Modular design, adjustable speed | 90% | 20 | 7 |

| Industrial Blenders | Variable speed, energy-efficient | 93% | 18 | 8 |

| Flow Wrappers | Flexible packaging, high speed | 94% | 10 | 9 |

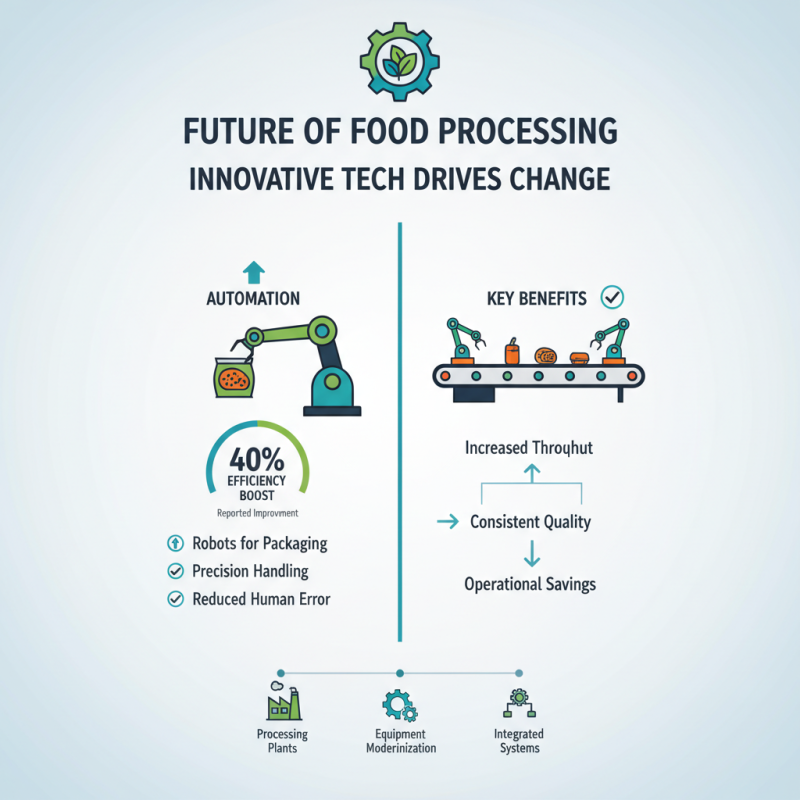

Innovative technologies are reshaping food processing equipment. Automation leads the charge. According to a recent report, automation can improve efficiency by up to 40%. Robots are increasingly used for packaging and handling tasks. They reduce human error and enhance precision. This trend is evident in various processing plants.

AI-driven systems also play a critical role. They monitor processes in real time, adjusting parameters for optimal performance. A study estimates that these systems can cut down waste by up to 30%. However, the implementation of such technologies isn't always seamless. Compatibility issues with legacy systems often arise. Moreover, the high initial investment can deter smaller businesses.

Sustainability is another key focus. Equipment designed for energy efficiency is becoming essential. Many companies aim to reduce their carbon footprint. Data shows that equipment utilizing renewable energy can lower operational costs significantly. Yet, achieving a balance between innovation and environmental responsibility remains a challenge. Some companies struggle to adapt to new regulations. Reevaluating strategies often leads to missed opportunities for growth.

Food processing machines come in various types, each designed for specific applications. For instance, mixers blend ingredients thoroughly, ensuring uniformity in products. They are vital in bakery and dairy industries. These machines save time and increase productivity but can sometimes lead to inconsistent textures if not monitored.

Another important type is the food cutter. These machines chop, slice, or dice ingredients rapidly. They improve efficiency in large-scale operations. However, improper settings can result in uneven cuts, affecting presentation. Precision is key to maintaining quality, especially in high-stakes environments.

Packing machines play a crucial role in preserving food. They automate the packaging process, which reduces human error. This is essential for maintaining hygiene standards. Yet, if machines misalign, products may be poorly sealed, compromising freshness. Balancing speed and accuracy is a common challenge in food processing.

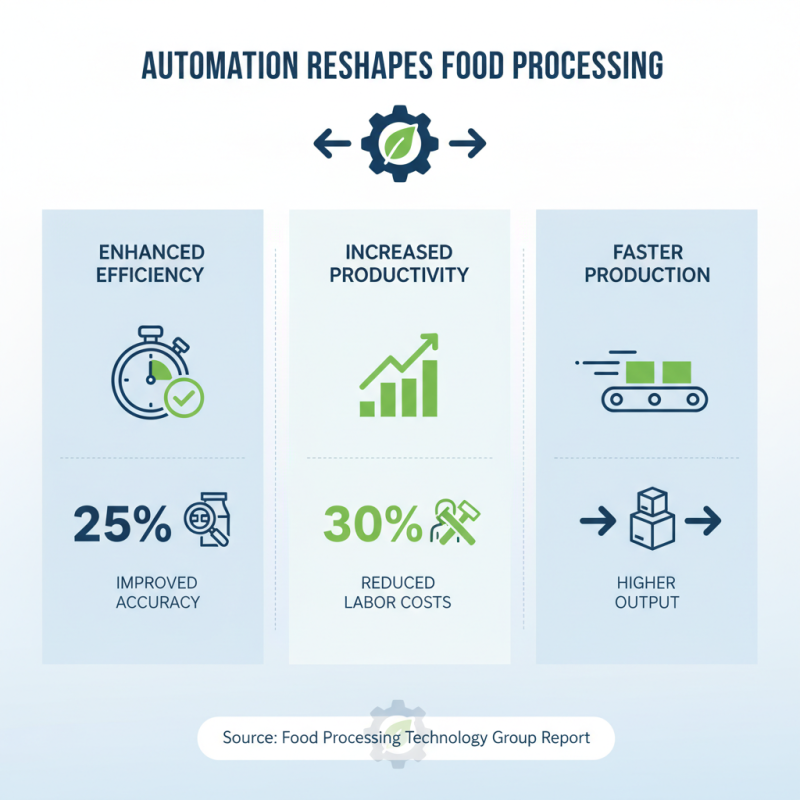

Automation is reshaping the food processing industry. It enhances efficiency and productivity significantly. According to a report by the Food Processing Technology Group, automation can improve accuracy by 25% and reduce labor costs by up to 30%. Machines can handle repetitive tasks. They minimize human error and speed up production lines. This increased speed can lead to higher output, which is vital in today’s market.

However, the transition to automated systems is not without challenges. Many facilities face upfront costs and the need for skilled labor to operate advanced machinery. Some workers may feel threatened by automation. A survey by the International Society of Automation revealed 40% of workers worry about job security in automated environments. Companies must address these concerns carefully. Training and reskilling initiatives are essential to ease the transition.

Additionally, the impact of automation on product quality cannot be overlooked. While machines can enhance consistency, they may also require regular maintenance. A breakdown in machinery can lead to production delays, affecting overall efficiency. Balancing machine reliance with human oversight is a crucial reflection point for operators in this evolving landscape.

The future of food processing machinery is evolving rapidly. Automation plays a key role in enhancing efficiency. Robots are increasingly used for packaging and sorting. They reduce human error and increase speed. However, integrating these technologies can be challenging. Not every facility is ready for such changes.

Sustainability is another vital trend. Machines designed for energy efficiency are in demand. They minimize waste and lower operational costs. Yet, many companies hesitate to invest in new technologies. The initial cost can be daunting. Training staff on new systems also poses a significant hurdle.

Innovation in food processing includes smart technology. IoT-enabled machines collect valuable data. This helps optimize production and reduce downtime. However, the complexity of these systems can lead to confusion. Some operators struggle to keep up. Balancing innovation and practicality is essential for long-term success.