In the competitive landscape of pet food production, efficiency is crucial. The right pet food processing machine can significantly impact overall productivity. While manufacturers strive for optimal performance, choices can be overwhelming. Each machine’s capability, setup, and maintenance needs vary widely.

Selecting the proper technology isn’t just about cost. It involves understanding your production requirements. Some machines offer speed but may compromise quality. Others focus on quality but slow down the process. It’s essential to find a balance.

Innovation in pet food processing machines continues to evolve. New designs bring promise, yet they also raise questions about adaptability. Producers must reflect on their unique needs and future growth. Doing so can help navigate the complexities of modern pet food production.

Understanding the importance of pet food processing machines cannot be overstated. These machines play a crucial role in ensuring quality and consistency. Efficient processing leads to better nutrition and palatability. Manufacturers can streamline operations, resulting in cost savings and improved product output.

Tips: Regular maintenance is vital. A well-maintained machine operates more efficiently. This reduces the chances of unexpected breakdowns. Training staff on machine operation is essential. Skilled personnel can troubleshoot issues quickly.

Quality raw materials should always be sourced carefully. Poor quality inputs can lead to processing issues. Monitoring the production line is necessary. It ensures that the products meet safety and quality standards. Having an inspection system in place can help catch mistakes early.

Investing in the right technology can enhance operational efficiency. However, it’s important to evaluate cost versus benefit. Not all machines are necessary for every operation. Sometimes, sticking with older machines can suffice. Reflect on what works best for your specific needs.

Efficient pet food processing equipment is crucial for optimizing production. Machines designed for this purpose should prioritize reliability and speed. For instance, extruders are vital. They mix raw ingredients evenly, ensuring consistent texture. A good extruder also minimizes waste, which can otherwise lead to increased costs.

Additionally, machinery that offers easy cleaning features can save significant time. This is essential in preventing cross-contamination of flavors. Operators often overlook this aspect, leading to inefficient practices. Furthermore, user-friendly interfaces can reduce training time for staff. Many processing lines struggle due to overly complex controls, hindering production flow.

Flexibility in processing options is important as well. Machines should accommodate various recipes and ingredient types. This adaptability allows manufacturers to respond to consumer trends swiftly. However, manufacturers sometimes invest in overly specialized equipment, resulting in missed opportunities. Balancing specialization and versatility is a challenge that requires careful thought and reflection.

Pet food processing machines play a critical role in the efficiency of production. The industry saw a significant growth rate of 4.8% from 2021 to 2026, according to a recent market analysis. Key machines include mixers, extruders, and ovens. Each one serves distinct functions that enhance productivity while ensuring quality control.

Mixers are essential for achieving a uniform blend of ingredients. They improve the consistency of pet food formulations. On the other hand, extruders cook and shape the food, allowing for a variety of textures. Ovens are key for drying and ensuring shelf stability, greatly reducing spoilage rates.

Interesting to note, reports indicate that overprocessing can impact nutrition, leading to considerations around automation levels in production.

Tips: Regular maintenance of these machines is vital. Wear and tear can lead to inefficiencies. Operators should frequently check calibration settings as slight variations could influence product quality.

Investing in upgraded technology can also be crucial. Automation can enhance speed, but relying too much on machines may overlook human oversight. In a world of increasing demand, balance is important to keep production both efficient and mindful.

When it comes to pet food manufacturing, several factors influence

production efficiency. One major aspect is the choice of processing machines.

Advanced extrusion technology, for example, can significantly improve the

consistency of kibble. A study indicates that companies utilizing high-performance extruders

boost their output by up to 30%. However, the initial investment can be a barrier

for smaller producers, requiring careful financial planning.

Another factor is ingredient quality. Premium ingredients may slow down the

production line but enhance the final product. A balance must be struck between quality and efficiency.

Reports show that manufacturers often face challenges with ingredient sourcing, impacting overall

productivity. Understanding supply chain dynamics is crucial to

maintaining a steady flow of high-quality ingredients.

Tips: Regular maintenance of machines can help avoid unexpected

downtime. Also, training staff on new technologies can reduce errors and waste. Metrics tracking can reveal

areas for improvement. Small adjustments might lead to substantial gains in efficiency,

even if they seem minor at first glance.

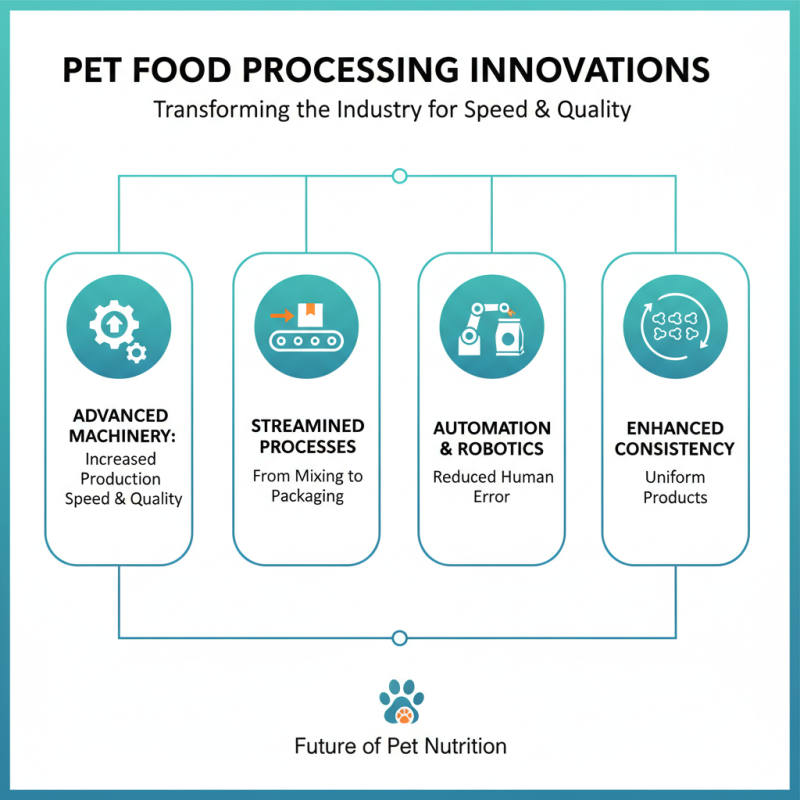

Emerging technologies in pet food processing are transforming the industry. Advanced machinery enhances production speed and quality. These innovations streamline processes from mixing to packaging. Automation reduces human error and increases consistency in pet food products.

Integrating robotics in production lines can significantly improve efficiency. Machines can operate continuously, minimizing downtime. However, the initial costs of technology may be a concern for smaller businesses. Investing in training is essential as well; employees must adapt to new systems.

Tips: Regular maintenance of machinery is crucial. A malfunction can disrupt production and lead to losses. Stay updated on technological trends. Evaluating your production methods can reveal areas for improvement. Embrace change, but reflect on how it aligns with your business goals.